Whisky, in all its iterations, is not just an end product, not just a drink...though it is a good one at that. It is a science, an art, alchemy and magic, geography and history, and it is people (um, not like soylent green...). There are many exemplary sites out there on the making and tasting of whisky, and I don't intend on reinventing that wheel. I just want to bring some story to what I think is a fascinating process.

You can see more whisky photographs as well as not-just-whisky photographs and ramblings if you follow the links in the sidebar. Please take a look...or not.

March 6, 2012

small is beautiful

Perhaps more delightful was meeting Mrs. Cuthbert and their young daughter. After Frances drove away on his tractor, I sat in the car writing a few notes. Hazel came out to make sure I had not missed Frances, and graciously spent some time chatting.

Daftmill is a beautiful little distillery for many reasons, not the least of which is the people who live and work there.

Slàinte

March 21, 2011

not scotch

The first photo shows the distillery as the white building on the left. Behind it up the hill are the half dozen log chalets maintained by the distillery's Inn operation, where my parents and I stayed when visiting the area. The rest of the photos are self explanatory. Like many good single malts, these pix are almost 10 years old.

Slàinte

February 16, 2011

raison d'être

I feel honoured to be in such company, having conceptualized this project quite independently of the Macallan and Albert Watson. My phone lines are open for future consideration (which emoji indicates one's tongue firmly implanted in one's cheek?).

Slàinte

February 8, 2011

February 1, 2011

more Tomatin

Slàinte

December 28, 2010

barrels

And though the distiller appreciates the barrel for the qualities of its wood, I appreciate it for the qualities of its shape and form...the smooth flowing line of the circle, the rhythm of repetition, the stories it tells by its grizzled exterior and stencilled tatoos. They're fun to photograph.

Slàinte

...and Happy Hogmanay

October 29, 2010

on malting

The first two are a couple photos of barley quietly germinating on the malting floor at Laphroaig. It's time, labour, and space intensive to malt this way - that's why few distilleries do it for themselves any more. I'm thinking the process was only undertaken after the establishment of distilleries as legal entities able to occupy a relatively large footprint, the first arguably founded sometime during the last quarter of the 18th century. Prior to the luxury of a malting floor, I suggest that most Scotch whisky must have been made with unmalted barley.

I also suggest you pick up one of Iain Banks's works, with or without the M. His "Raw Spirit" got me reading him, and though it is not quite representative of his more widely distributed subject matter the book is a tasty dram, a roadtrip through the landscape of Scotch whisky.

a grain wheelbarrow at Laphroaig used to spread the steeped barley by hand across the malting floor

you've seen a similar image here before - raking the growing barley at Bowmore so it doesn't mat together into a tangled mess

a motorized barley rake at Laphroaig - undoubtedly a lot easier on the maltman's back!

after two days on the malting floor after three days on the malting floor

the malting floor at Springbank, Campbeltown

the malting floor at Kilchoman, Islay

October 6, 2010

tribute

We had a wonderful tour of their maltings in 2008, very informative and personal, with Heather Anderson, the distillery manager's wife. The maltings may still be operating, I don't know. When you get to meet the people who have a direct role in the crafting of our whisky, one feels a modicum of personal loss when a distillery like Tamdhu is considered redundant by its corporate owners. One wonders what happens to the people you've met...here are a few of them.

...another one bites the dust

...peering into the barley screener

...emptying the steeped barley

...casting the steeped barley to the Saladin box for germination

...emptying the Saladin box, the barley being ready for the kiln

See www.whisky.com/brands/tamdhu_brand.html for more information on Tamdhu.

Slàinte

August 15, 2010

the rant

Jump to the present. Most distilleries now do not allow photographs to be taken in any of the production areas. Apparently this is for health and safety reasons - a common excuse being the prevalance of explosive alcohol vapours. More likely the methane from this bull***t.

I welcome any industry comments on this. And I applaud all those distilleries which still allow whisky fans like me to have their photographic fun.

This clandestinely obtained photograph would have gotten me into trouble with the tour guide at Tomatin had I been seen.

A couple of Whisky Academy students at Bruichladdich get a lesson from Budgie...look out folks, my camera is going to blow you up! During past visits, the folks at the Laddie have given me free access to photograph in the distillery. One of the reasons I love the place.

Slàinte

July 18, 2010

"still" here

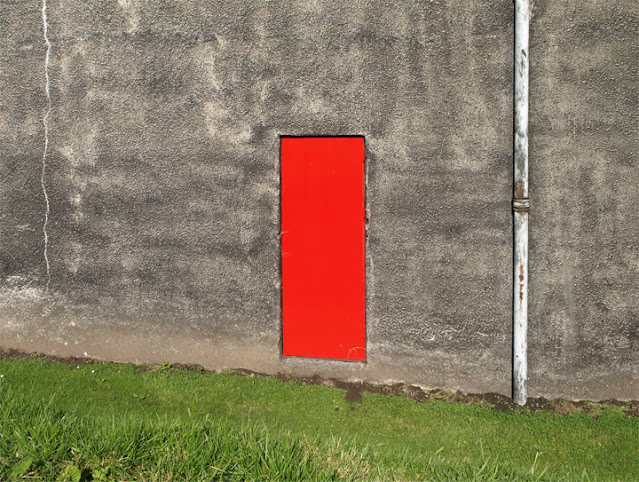

If you've managed to peruse my webalbum photos, or looked at my personal photoblog then you'll know that I'm quite visually drawn to splashes of the colour red. Or any colour for that matter. Aberfeldy, like many distilleries, was quite restrictive in allowing cameras to be used inside the distillery, so luckily there was some interesting stuff to see from the outside.

See you soon.

Slàinte

June 26, 2010

June 12, 2010

envying angels

You've no doubt heard of their "share", that portion of whisky alcohol which works its way through the wood of the barrels basking in the warehouse over time and which apparently disappears into the ether. Well, this vapour actually doesn't totally disappear. Some of it is rounded up and feasted upon by a mould or microfungus called Baudoinia compniacensis. This is the black sooty stuff often seen on the outside walls of distillery warehouses. Some distilleries whitewash the walls to cover it up. Too bad I say...it is an integral part of the making of your favourite dram. At every turn we seem to be increasing the divide between ourselves and the natural world. How can we expect people to respect the natural environment if we are forever demonizing it?

So, how many angels can dance on the head of a pin? At least we know why they're dancing.

A Tamdhu wall...but it could be any whisky warehouse wall.

Slàinte

May 24, 2010

more heat

A couple of the photos have an annoying lens shadow at the bottom of the image, for which I apologize. I would normally not hesitate to excise such offences to my aesthetic sensibilities, however I felt that the subject matter would have suffered somewhat if I had cropped them out. So be it...I'll just have to do the suffering with a cringe or two every time I see them.

Forsyth's, in the town of Rothes in Speyside, have been crafting the lions share of Scotch whisky distillery equipment since the end of the nineteenth century. Dad and I were lucky enough to be graciously hosted by Mr. Richard Forsyth on a very interesting tour of the factory. I suspect this is the upper section of a still in the making. After having been heated by another coppersmith with a torch, this chap is beating the red hot metal into shape. The outer shell of a condenser is lying on the floor behind him.

Bowmore is one of the few remaining distilleries to floor malt some of their own barley. While germinating, the barley produces heat which must be regulated by turning over with wide flat shovels and raking, which is being done here. This also prevents the emerging rootlets from tangling into an unmanageable clump. As you can see, this process is quite labour intensive and back breaking so it is also done by machine.

This is a rare sight - too bad I messed it up with a shadow (cringe #1!). The inside of Springbank's wash still with one of the few rummagers in existence. When a still was (is, in this case) directly fired with an open flame from below, as all stills used to be, there needed to be a method of preventing the contents from scorching. This was achieved by the rummager, a strip of copper chain mail which revolved inside the still in order to stir and scrape the bottom, not unlike what needs to be done when you make your porridge on the stove. This still is also heated by steam which travels through the pipes seen around the circumference.

The interior of a Glen Scotia still. The silver pots radiate heat from steam inside the pipes which can be seen just below the liquid surface. They, of course, would be covered when the still is in full tilt boogie mode (one of the lesser known whisky distilling terms!...and an obtuse shoutout to Canadian backup bands everywhere!!).

The charring of the inside surface of whisky barrels is done in a couple of ways. At the Speyside Cooperage where they refabricate zillions of barrels for the Scotch whisky industry, the barrels are stood upright with no ends above a furnace which blasts a huge flame through the barrel like a chimney. Very cool sight. This photograph, however, is from the cooperage at the Balvenie where they do all their own barrel work on site. You're looking at the end of a barrel on its side, through a window I might add, which is being spun round by the two rollers at the bottom of the image. A flame is then blasted into the open end facing away from us, which can be seen shooting out the bung hole. It, too, is a pretty cool sight to see.

This is one of my favourite barrel images, so I'm glad to be able to share it with you to end off this post. It is a triptych of Bruichladdich barrels, with one showing the result of the interior charring (or maybe it's from all of my hot air floating about!).

Slàinte

May 10, 2010

the heat is on

Quite a lot of distillery tour guides will tell you of the happy cows which are fed the draff or spent grains left over from the mashing process. Glenfarclas also incorporates their pot ale or spent wash into the draff for livestock feed, a byproduct which has traditionally been disposed of by most (I'm guessing) distilleries. Bruichladdich is looking into the creation of methane from their pot ale, using it to help power the distillery. I'd like to think that waste heat recapture is high on the list of research into the further improvement of distilling efficiency. We humans are a wasteful lot, and must get to a point where the byproducts of human activity cease to be considered waste but moreso as raw material for some other industrial process or human endeavour. Every natural process is part of a closed cycle, and human industry should be no different...Am I grandstanding again?

The main use of heat in a distillery is, of course, to separate the alcohol from the rest of the liquid within the stills by evaporation. And in order for us to be able to drink it, it must be condensed into a liquid again. This is the job of the aptly named condensers, those big copper columns which are often seen standing beside and connected to the stills. In some distilleries they are situated outside, for lack of space or to keep them cooler (another guess there). The vapour coming off the still is sent through the condenser where it circulates around a series of smaller tubes running the length within it. These tubes hold cold water which takes the heat from the vapour allowing it to condense back into a liquid. This is one of the processes which we are unable to see happen during that tour of our favourite distillery.

However there is another, older technique for condensing the vapour coming off the stills and that is the use of wormtubs. The function is the same but the technology is a little less sophisticated (arguably?). The vapour passes through a tube which "worms" its way in a circular path down through a large "tub" of cold water, usually outside.

At the top are Kilchoman and Bunnahabhain. The third photo shows the wormtubs of Abhainn Dearg, which are inside and sit above the two stills. The last photo shows the outside tubs of Cragganmore. I bet these would make dandy hottubs during a chilly winter. Dram in hand, soaking in the soothing warmth while snowflakes gently caress your face...mmmmmmm.

Slàinte

April 12, 2010

food for thought

Consider this...10, 12, 15 years ago (18, 21?...lucky you) the whisky in your glass was a plant, struggling in the soil for survival, seeking out its own water of life. Barley. If lucky, it experienced the right environmental conditions to grow into a strapping young kernel. If not, then it returned to the soil to help nourish the next lucky one. But it was a living thing nonetheless.

All too often we disregard the history of the food we put into our mouths in order to nurture our bodies. If we considered where our food comes from a little more, then perhaps we'd be less inclined to mistreat the gardens of our very existence, the air, water, and soil which give us life. You'd better take a sip, I think I'm getting too melodramatic here.

Back to the barley. It never ceases to amaze me that whisky is just that, plus water and yeast, which is also a living thing. And if you want to get really metaphysical, so is water. In the end, is it any wonder that whisky gained its name from the Gaelic term uisge beatha, itself descended from the Latin meaning "water of life".

There aren't many distilleries which are able to facilitate the entire cycle of whisky making from barley to bottle. Many don't strive to, but some make it a part of their mission statement. It takes a lot of homegrown barley to satisfy an entire mashbill. Even small distilleries like Kilchoman on Islay only presently grows 30% of their own, and they don't (yet) have a bottling facility. The young Abhainn Dearg on the west coast of Lewis is giving it a go, if the Atlantic lets them. Not sure how much Islay barley Bruichladdich manages to bring in, but they may be the closest to the goal, even though they don't malt at the distillery.

So, this blog entry is in celebration of the lowly barleycorn, that often overlooked but essential first component that is the root of all whisky, from which all our drams stem, the seeds of our mal(t)content...OK, OK, here are the photographs.

Here, Islay birds feast on what John Barleycorn didn't get.

Slàinte

April 8, 2010

a couple of my faves

The journey of a thousand miles begins with a single step. My first steps will be about two of my personal favourite single malts, Bruichladdich and Laphroaig. Both distilleries are on the Isle of Islay, part of the Inner Hebrides off the west coast of mainland Scotland. Maybe someday I'll put up a map of Scotland and all her distilleries, or find a link to a good one...remind me, would you please?

The Laddie is on the west coast of Loch Indaal, in the village of and just north of the Bruichladdich pier from which this photo is taken. Loch Indaal is a long and fairly wide body of water, open to weather coming from the southwest across the North Channel from Ireland and the Atlantic. The distillery and warehouses are situated just across the road from the loch.

Laphroaig is on the south coast of Islay, sheltered somewhat by Laphroaig bay. I say somewhat because it can still get lashed quite severely by storms blowing in from the southwest. It has warehouses directly on the shoreline.

I'll be highlighting distilleries in no particular order and will be putting up photos on an irregular basis, especially if I revisit the distillery in the future, so please don't hesitate to return.

Slàinte